Tyre Pyrolysis Plant Cost Should Really Be Regarded

Tyre pyrolysis plant costs certainly factor in the equation, but there are many important points to help make here while you prepare to choose how you need to recycle your waste. First, as soon as a plant has become installed, it basically runs itself in terms of both energy and operation. Second, you stand to make considerable profits when you have enough waste to give the appliance daily.

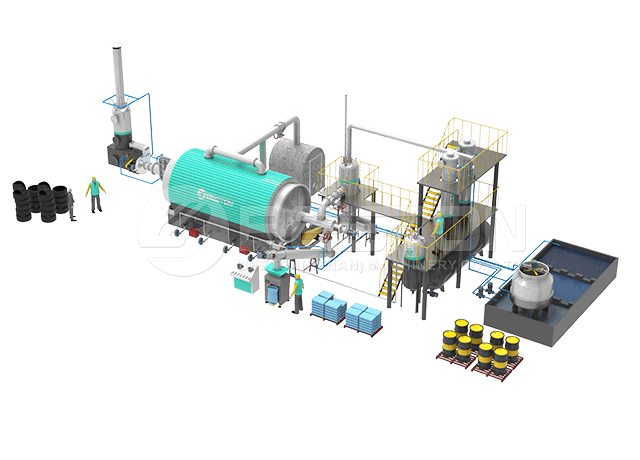

How does the plant run itself? There are actually four raw materials which come from recycling waste tyres through the pyrolysis process. One of these is pyrolysis oil, which actually will probably power the plant. You're not planning to come near to using each of the oil, however, and you may then generate profits from two out of your other three raw materials.

Do you know the other three raw materials? These are carbon black, the steel from the tires and gas. The gas you are supposed to use in house, and therefore the steel and carbon black can make you some serious money. The steel will just help out matters, since you will only net a certain amount. But you will definitely get quite a lot of carbon black, which happens to be extremely marketable.

Just how much can you make away from your operation? That is going to depend on simply how much raw material you might be feeding the appliance. You will have to deduct the initial cost of tire recycling plant, too, and then start crunching all of those other numbers. Calculate the daily amount of waste, net raw materials and what you can profit, and total that up for a while period of five-years.

When your machine lasts longer than five years, then you certainly are in position to make more money. The goal the following is to produce this venture profitable while doing what's great for the planet with all the waste materials you have in your facility. With all the right connections, you could potentially make quite a lot of money within the next a few years.

To be certain, this kind of recycling project must be right for your company. Should you don't have the amount of raw materials expected to feed the equipment and turn a return, then you're not intending to make financial feeling of your investment. Nevertheless, you likely wouldn't look at getting a tyre to oil plant if you didn't have a great deal of raw materials on hand.

What for you to do now could be price these plants by speaking with the very best manufacturers. The greater capacity plants are going to set you back more. You need to know a smaller continuous pyrolysis plant continues to be likely to process tons of waste tyres on a daily basis.

Nevertheless, make an effort to minimize your investment while still having the best machine for your personal facility. You wish to break even real quickly and commence stacking in the profits using this recycling venture. It can be possible to achieve that if you opt for the proper machine. Are you prepared to determine which manufacturers make the most efficient tyre to oil plants on the market?